cGMP Warehouse

Client maintains a 145,000 cGMP pharmaceutical product distribution center in Kentucky. The facility is comprised of warehouse with office support space. The warehouse area contains high bay refrigerated/freezer storage rooms as well as space that accommodates product storage at ambient conditions and packaging equipment. The majority of freezing is accomplished with refrigerant based systems. However, several smaller systems/chambers are cooled with dry ice and liquid nitrogen.

Bala has also worked with the client on multiple renovations for more than a decade. Projects included:

- Clean Room Packaging Suite

- Renovation of a 4,000 SF cold room into a clean packaging suite handling pharmaceutical materials maintained at -70OF. Since the pharmaceutical materials are stored with dry ice, the mechanical systems included CO2 gas monitoring and appropriate ventilation to protect personnel.

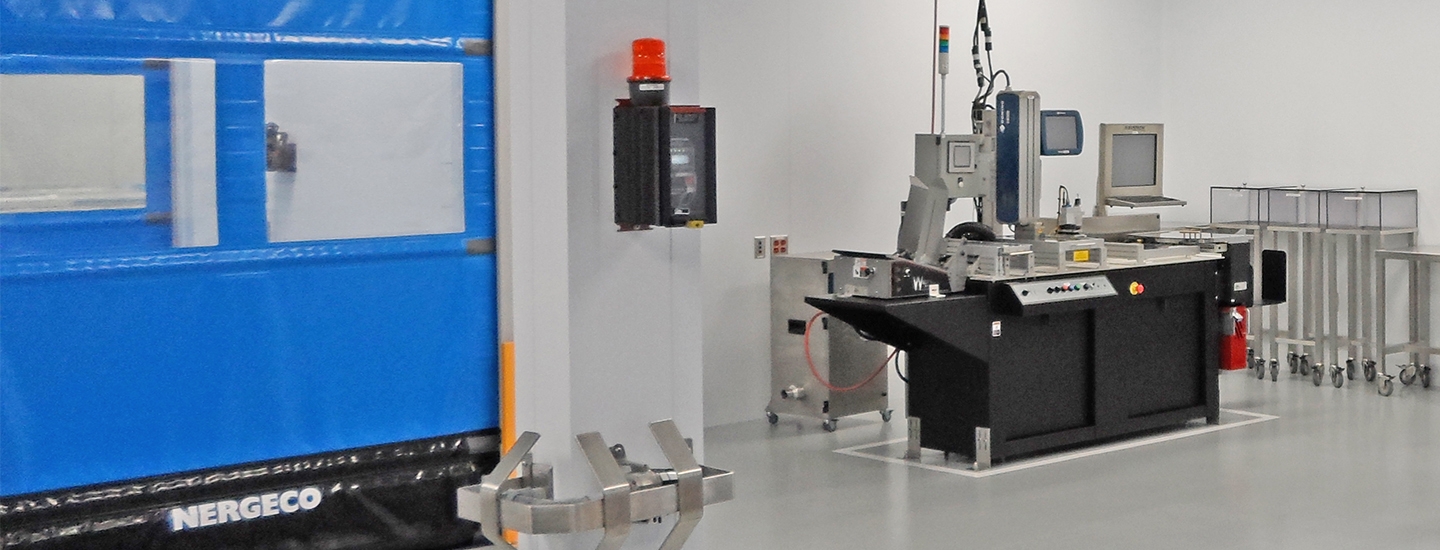

- Vial Sleeve Label Room

- Renovation of warehouse space into a 500 SF ISO 8 clean room to house vial sleeve labeler as well as gowning area.

- Cell Bank Cryo Freezers

- Existing cryogenic freezers at the site were expanded to 1,500 SF to accommodate twelve (12) vessels relocated from another site. The existing liquid nitrogen bulk storage tanks supplied the new freezers via a new liquid nitrogen distribution system. Additional venting was incorporated at each cryogenic freezer to eliminate release of nitrogen gas into the occupied area.

- Blast Freezer

- Relocation of blast freezer operations encompassing 1,000 SF with a -70OF blast freezer, seven (7) gel pack freezers, packing materials and pallet storage as well as the addition a new 500 SF cold room vestibule space to accommodate forklift traffic entering and egressing from a -30OF freezer room.

- Cold Room Replacement

- Replacement of refrigeration equipment serving a 6,000 SF cold room with air distribution improvements accommodate high racks and forklift traffic while maintaining temperature uniformity. During the design phase, infrared scanning was performed on the interior surfaces of the exiting cold room panels to determine areas that needed to be sealed.