Life Sciences

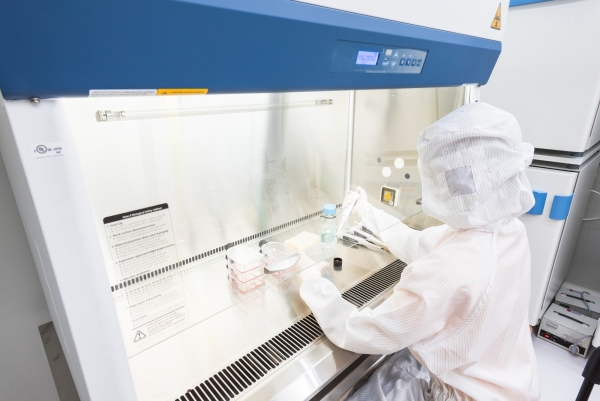

Adapting spaces to new lab technology and ever-evolving scientific research.

The rapidly changing technologies and scientific methods have increased demand for sustainable modular designs that are flexible and resilient to minimize operational disruption as future modifications are implemented. We apply this approach to any design whether it involves research, vivarium, clean, and small-scale production/manufacturing spaces.

Bala’s expertise in the life sciences market includes new construction, expansion, conversion and renovation projects, as well as modernizations to adapt spaces to new technologies and ever evolving scientific research.

- Modular and flexible designs are important to limit the extent of future modifications necessary to accommodate ever changing research. Flexible designs allow renovations to be made quickly at less cost while maintaining operations in adjacent spaces.

- As part of the design process, Bala works with lab personnel, architects and owners to program the spaces and build criteria that forms the foundation of the design.

- Projects are delivered in a multitude of ways, including early release packages, design assist and design build.

- Speed to market approaches have become more prevalent to accommodate supply chain issues.

- We develop design that are flexible so that the design team can pivot during construction to meet today's challenging supply chain issues.

- Labs cover a wide range of specific uses from tissue culture, radio isotope, microscopic through QC; each requiring specific designs.

- Specialized labs may include dry (extremely low RH), NMR, or cold and freezer rooms requiring ventilation air and dehumidification systems.

- Though labs have specific functions, they still need to be designed in a modular, flexible layout to keep with changing technology/research, and allow for upgrades without impacting still operating adjacent lab spaces.

- Pharmaceutical companies collaborate and are interested in Industry Benchmarking when establishing criteria.

- Designs may encompass a balance of company/industry standards.

- Company environmental and health personnel are important members in the design team.

- Funding sources and grants may influence design criteria.

- cGMP spaces may include research labs, manufacturing, packaging and warehouse.

- Flexible designs accommodate different manufacturing processes and changing technologies. Equipment may be fixed or portable.

- Spaces may require clean room classification or be designed to these standards.

- More tightly controlled space and secured access.

- Hazop reviews.

- Systems need to accommodate regulatory tracking requirements.

Clean research spaces prioritize resiliency, reliability, safety, and energy efficiency.

- Clean spaces may be sterile environments under positive pressure or potent compound, requiring containment and multiple levels of decontamination.

- Clean spaces require increased airflow, hazop reviews and must be designed for each client's unique clean space standards.

- Utilizing prefab construction and systems can reduce costs and installation timelines.

- Systems must be designed for low vibration and noise, as well as resilience and 24/7 operation support.

- More tightly controlled space conditions and access controls may vary by species.

- Support spaces have more robust infrastructure needs.

- Industry benchmarking is important when establishing criteria.

- Systems need to accommodate regulatory tracking requirements.

- Spaces are a blend of traditional laboratories, requiring unique design elements of each.

- Similar to academic, research space needs to be highly flexible to accommodate changing demand and technologies.

- Designs need to accommodate healthcare and laboratory standards.

- Funding sources and grants may influence design criteria.

Academic research and teaching laboratory needs differ from commercial lab spaces.

- Labs are designed for many, frequently changing users with very efficient layouts.

- Labs accommodate a multitude of functions.

- Institutional standards must be incorporated into the designs.

- Labs often require upgrades of older systems to meet demands of cutting edge research.

Speed to market is key for office to lab conversions. A thorough evaluation of the space, the costs and program requirements is critical for project success. Some unique considerations include:

- Multi-tenant space needs differ from single-tenant.

- Urban high-rise buildings present unique challenges.

- Floor-to-floor heights present potential limitations.

- Identify the capacity of on-site utilities.

- Modular or flexible design offer the resiliency needed for incubator labs.

- MEP/FP Engineering

- Technology Systems & Security

- Structural Engineering

- Lab Conversion Facilities Assessments

- Energy Analysis & Lifecycle Costing

- Facility Programming & Lab Equipment Matrix Development

- Environmental Room Design

- Critical System Testing

- Process & Instrumentation Diagrams (P&IDs)

- Air Dilution Analysis

- Computational Fluid Dynamics

- Photometric Analysis

- Hazop Analysis

Sustainability

- Carbon Assessment

- Decarbonization Strategies

- Energy Auditing

- LEED and WELL Consulting

Commissioning (Cx)

- Third Party Cx

- Cx Project Management

- Infrastructure Testing

- OPR Development

- Operations & Maintenance Programs

- Cx Plans, Reports & Test Scripts

- Retro-Commissioning

- Peer Reviews